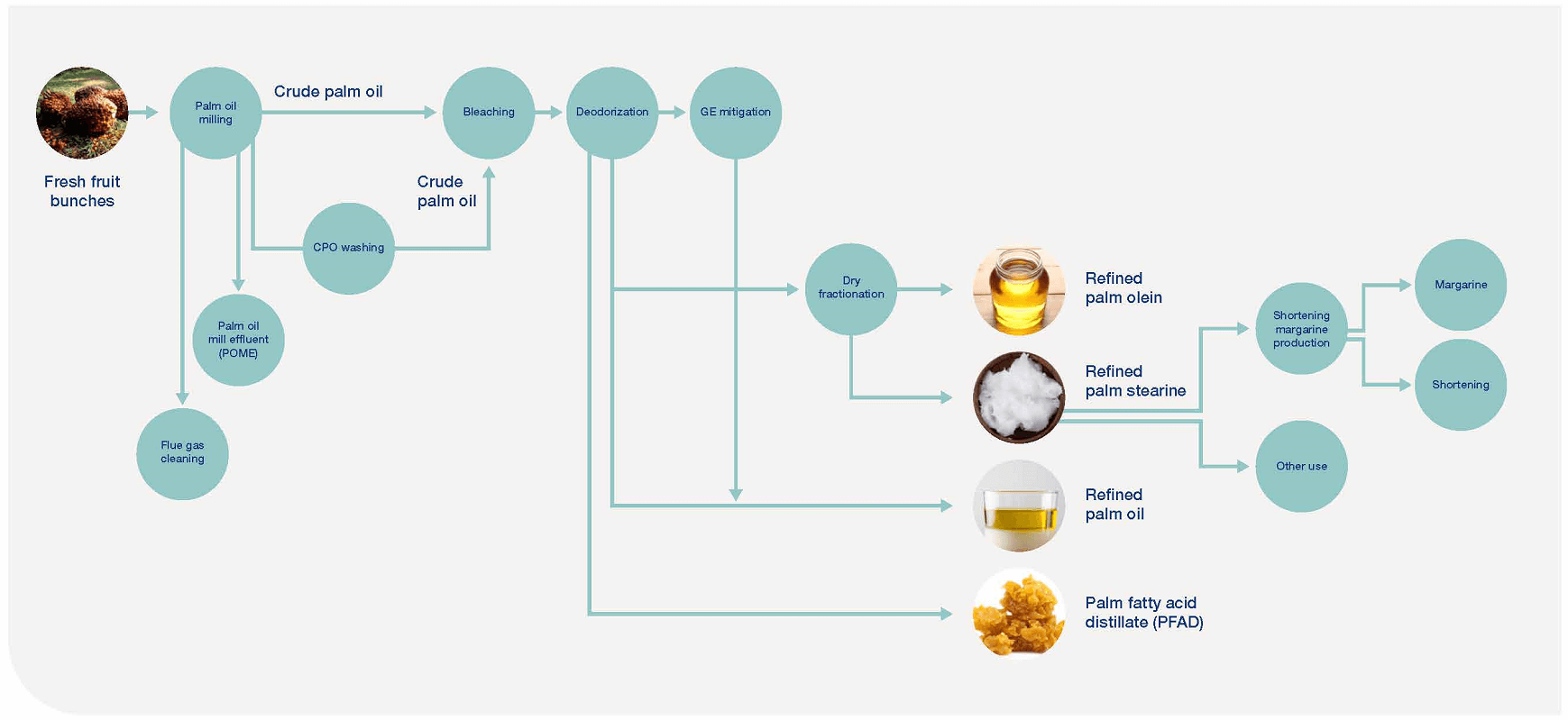

Palm oil processing

Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart processing solutions for the entire supply chain – milling, POME management, refining and more. Our complete range helps you increase yield while meeting increasingly strict environmental and health requirements. Along with a knowledgeable local service presence, it’s about you having the tools and support to achieve more profitable production.

First in palm oil processing with Alfa Laval

- A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing

- Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing

- Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

- Maximized energy efficiency for greater sustainability and reduced operational costs

- Continuous separation innovation from the leading developer of centrifuge and decanter technology for over 100 years

Our palm oil production process experts have worked closely with customers for decades, enabling us to better understand both the challenges and possibilities facing today’s mills and refineries.

Contact us today to learn more about how our solutions and service offering can help you to achieve long-term, reliable and more profitable operation.

Total solutions for palm oil processing

Optimizing the edible oil process

Turning crude oil into high-quality edible oil demands both expertise and precision. Alfa Laval brings extensive process knowledge across every refining stage – from degumming, neutralization, dewaxing, fat modification, bleaching, deodorization to GE and 3-MCPD mitigation. Our proven technologies ensure consistent quality, improved yields and greater efficiency while meeting food safety and sustainability requirements.

How can we help you?

Documents

Download

Application brochure

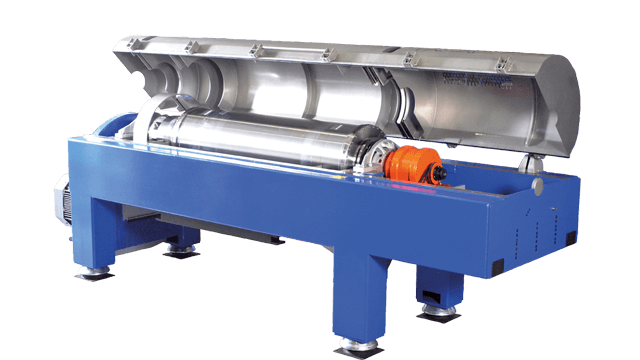

PANX 800 brings new possibilities to Ban Dung Palm Oil Industries

By investing in an Alfa Laval PANX 800 decanter centrifuge, Malaysian palm oil refiner Ban Dung has increased capacity while also reducing the level of product waste in their production. With improved energy efficiency, they have even achieved lower overall operational costs. Hear their story in this video.

Discover the Alfa Laval PANX series of palm oil decanter centrifuges for yourself.