AL-mem

The Alfa Laval Membrane-UF system is a cross-flow ultrafiltration plant which is designed for automatically controlled product concentration in continuous mode. The system provides cost-effective standardized solutions for specific concentration requirements and is designed with a minimal hold-up volume and a stringent focus on hygiene throughout

Applications

The Alfa Laval Membrane-UF system (AL-mem UF) is normally used as a concentration and purification stage within other processes, reducing the volume of a liquid by removing water and other low-molecular substances.

The AL-mem UF system can be used for cost-effective concentration of proteins, gums and other feeds prior to further evaporation. Units of this type are widely used for installations processing blood plasma, gelatine, egg, pectin extract, carrageenan and chitosane. Also for the production of natural colours and for the recovery of protein from waste streams these units are the ideal choice.

The actual process temperature is related to the particular feed product being treated. Typical temperatures lie in the range of 5 to 90°C (41 to 194°F).

Design

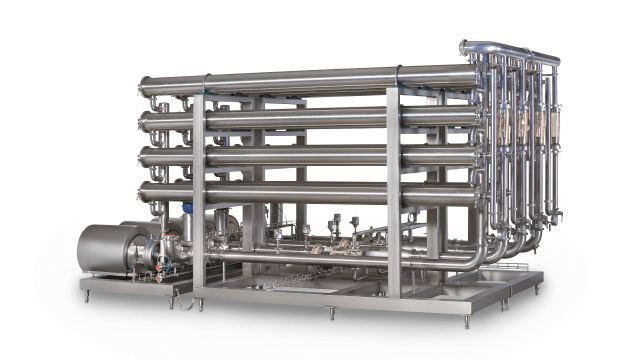

The Alfa Laval Membrane-UF system is supplied as a frame-mounted plant with pre-assembled components and prefabricated piping. It is ready for operation as soon as it is installed and connected to external supply systems.

The system offers easy, reliable operation along with straightforward maintenance thanks to its pre-assembled and frame-mounted setup. This helps keep downtime to a minimum.

The piping, pumps, strainers, valves and fittings as well as the control panel are all manufactured by Alfa Laval. This provides significant advantages in terms of effective service and reduced spare parts inventory.

All piping and equipment in contact with the product or cleaning liquids are of sanitary-level design, as are also the spiral membranes. Steel parts are made of AISI 316L stainless steel.

The AL-mem UF system is controlled and monitored via a PLC operator panel which includes a motor control centre equipped with frequency drivers on pumps to keep down energy consumption.

Product concentration and purification are conducted in continuous mode which is automatically controlled. Cleaning is based on operator controlled and monitored CIP procedures.

Benefits

- Frame-mounted modules with pre-assembled components and prefabricated piping

- Main components and control panel are manufactured by Alfa Laval

- All piping and equipment in contact with the product or cleaning liquids are of sanitary-level design. AISI 316L stainless steel parts

- PLC operator panel for system control and monitoring of data

- Automatically controlled product concentration in continuous mode

- Operator controlled Cleaning-In-Place procedures

How it works

Control system

The Alfa Laval Membrane-UF system features completely automated operation via the easy-to-use MemProC® control system. This includes separate modes for selecting production, cleaning, disinfection and water recirculation operations, complete with all the necessary sub-sequences. This ensures safe and reliable operation of the entire system.

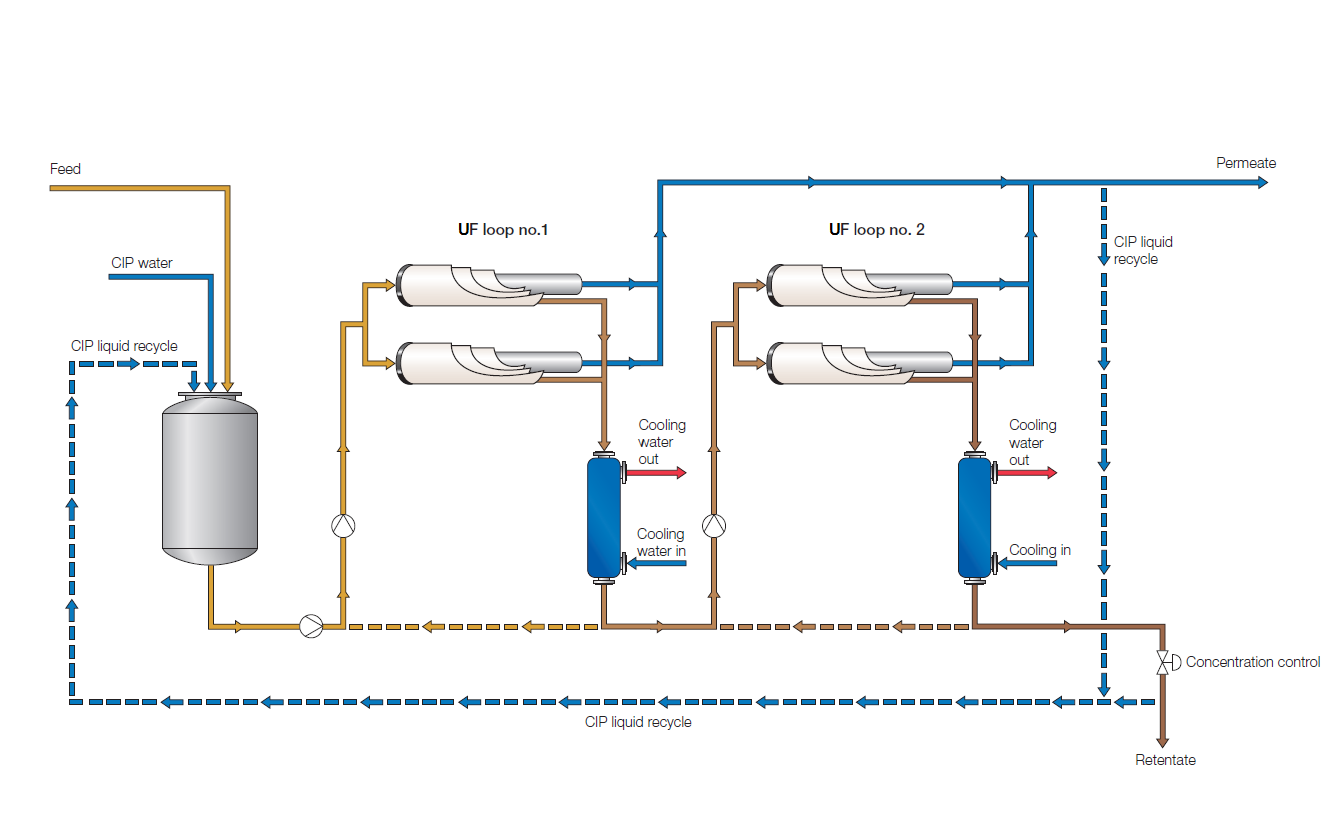

Membrane loops

The feed product is introduced into the feed tank system by the level control valve and pumped to a number of membrane filtration stages connected in series (loops). Each loop consists of a number of spiral modules containing Alfa Laval spiral wound membranes for ultrafiltration. These membranes permit salts and water to pass into the permeate stream whilst proteins, gums etc. are rejected and thus become increasingly concentrated as they pass through one loop after the other.

Pump and cooling system

In each loop, the recirculation pump system provides the membranes with the cross-flow rate that is appropriate for keeping fouling to a minimum, balanced against the overall capacity of the system. The unit also contains a cooling system for removal of any heat generated by the pumps.

Tank system

The permeate collected from the loops enters the permeate tank system where it is discharged upstream or downstream for either recycling or disposal via a drain system.

Flow rate control

The retentate flow rate output is normally controlled by a flow ratio system (VCF value) or by an optional refractometer/density in-line instrument to obtain the desired product concentration or volume reduction.

Product displacement and CIP

When a production cycle has been completed, the product is displaced out of the sytem by water to ensure maximum product recovery. This displacement sequence is followed by a water flushing stem to remove any product left behind on the membrane surface. Finally, a CIP sequence is conducted to clean the membranes and the loops.