ALDRUM G3

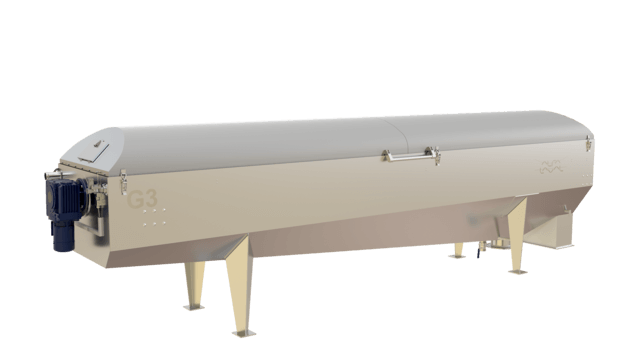

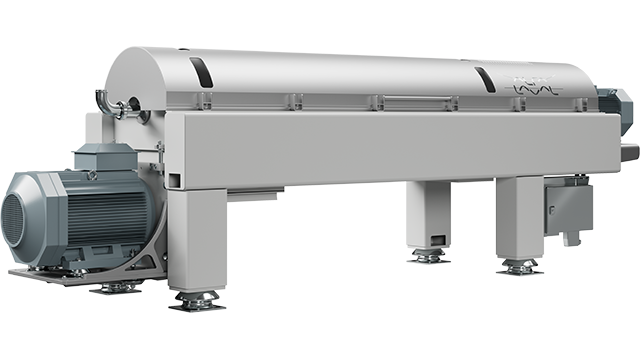

The Alfa Laval rotary drum filter Aldrum G3 sets a new standard for sludge thickening. The sludge thickener efficiently thickens sludge to optimize downstream processes, boosting biogas production and reducing dewatering costs. Its enhanced design, featuring a rotary drum filter and an efficient sludge hopper, improves performance while keeping operating costs low.

Experience the performance made simple with a groundbreaking sludge thickener

- Greater capacity from the same footprint

- Low polymer consumption, ensuring low operating costs

- Outdoor installation of the sludge thickener, if required

- Enclosed design for a clean, odourless working environment

- Simple maintenance with cleaning-in-place system that uses potable water, final effluent or treated filtrate

Sludge thickeners are optimal for medium to large capacity sludge thickening, enhancing process efficiency and achieving more cost-effective dewatering. Sludges that typically necessitate liquid polymer for flocculation and thickening can be treated with a more economical powder polymer, thereby reducing operational costs. The conveyor design of the sludge thickener enhances efficiency, while the cover switch and slam-proof cover improve safety. The Alfa Laval Aldrum G3 is capable of handling capacities ranging from 15 to 180 m³/h.

Rotary drum filter for medium-to-high-capacity sludge thickening

By utilizing advanced technology, including components like the rotary drum filter, the sludge thickener system enhances process performance while minimizing operating costs. It is suitable for a wide range of applications, including all types of municipal wastewater sludge, industrial separation (such as in paper production and solid waste processing), and fresh water production at waterworks. Additionally, the optimized design of the sludge hopper ensures efficient collection and handling, contributing to a streamlined sludge management solution.

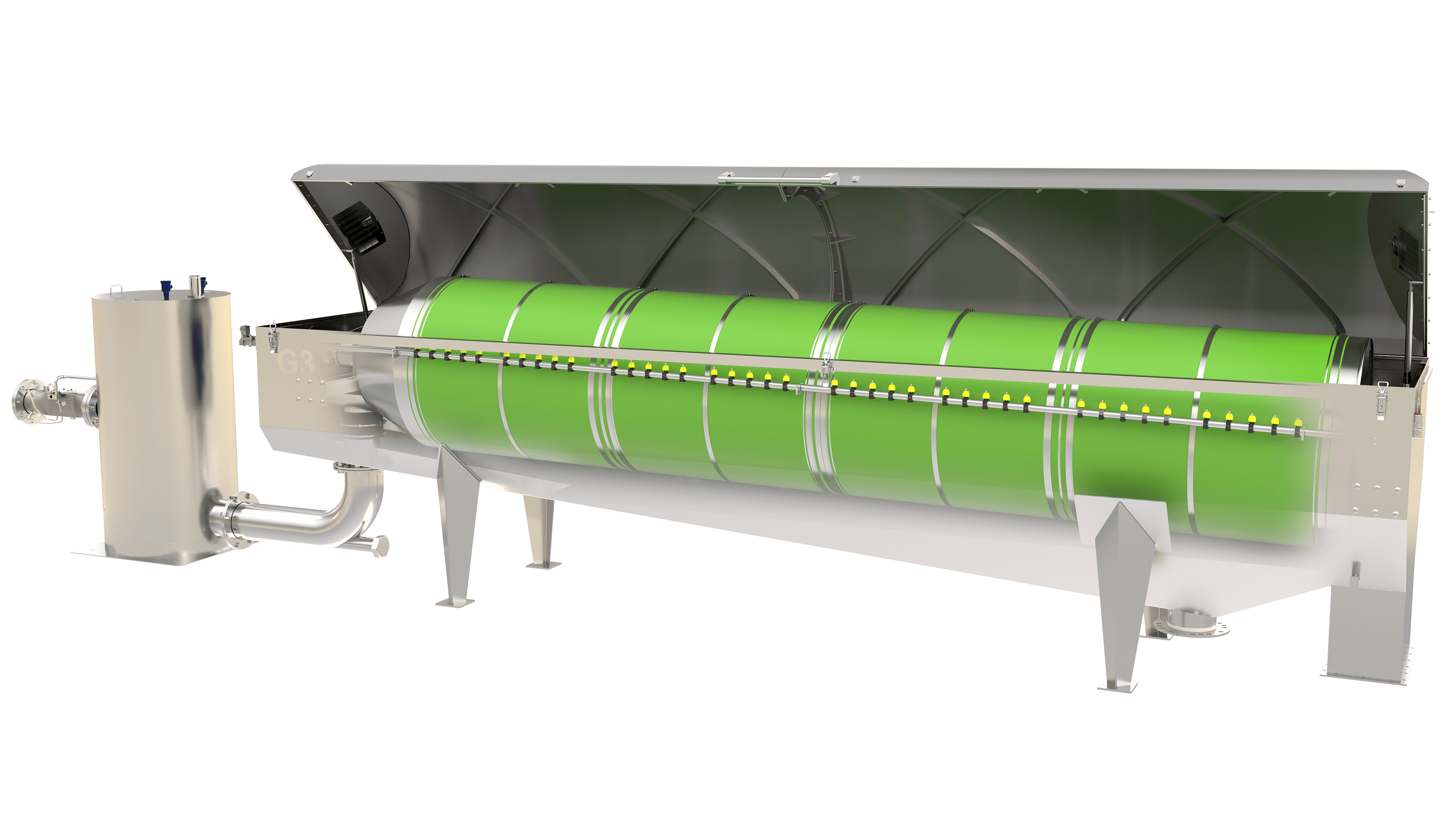

How it works

The ALDRUM thickener works on the principle of conveying polyelectrolyte-treated sludge (a.k.a. flocculated sludge) through a slowly rotating drum filter. The sludge remains in the drum while the water phase passes through the filter cloth.

You can achieve the most efficient thickening by varying feed rate, polymer type and dosage, drum speed and spraying interval. You get the most cost-effective flocculation and polymer dosage by installing a flocculation reactor and/or mixing valve upstream of the actual drum thickener. A variety of filter cloths are available for new applications.

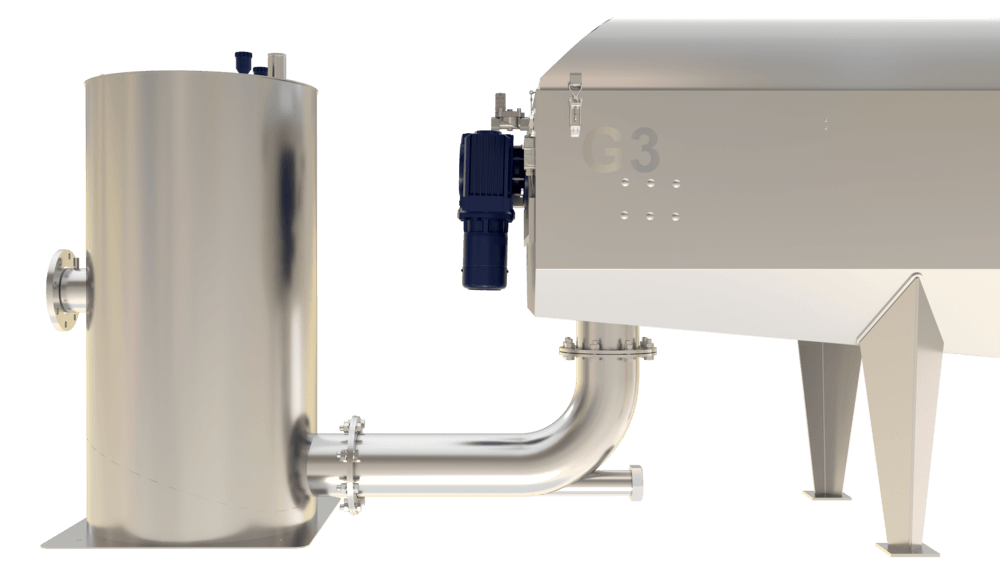

Discover our range of auxiliary equipment

- Mixing valve: Ensures thorough mixing of polymer and sludge, which reduces polymer consumption. Can be installed directly on to the drum thickener inlet or before the flocculation reactor

- Flocculation reactor: Simple open reactor that kick-starts the creation of large and strong flocks. Can be installed directly onto the drum thickener inlet

- Sludge hopper: Leads the thickened sludge to the sludge pump in a controlled and efficient manner

- Basic control panel: For easy control of the drum thickener, including control of the level in the flocculation reactor (if fitted)

- Advanced control panel: All-in-one control solution. Control of the plant’s feed pump, sludge pump and polymer pump, as well as the drum thickener, the level in the flocculation reactor and the sludge hopper

Sludge thickener equipment success stories

Related products for sludge thickening and dewatering

Contact us

We offer a complete range of solutions for wastewater treatment. With industry-leading technology and expertise based on the experience from thousands of installations, Alfa Laval experts can help analyse your unique situation and select the optimal equipment model, configuration and services for your needs and budget.