Header-and-coil

Alfa Laval Aalborg header-and-coil heat exchangers are designed for demanding heat transfer duties in applications characterized by high thermal loads, temperatures, and pressures – for example in energy storage facilities and CSP plants. The unique design ensures exceptional thermal performance and high operational reliability, even under cyclic conditions with rapid temperature variations. Contact us to discuss how you can benefit from Alfa Laval header-and-coil heat exchangers.

Benefits

- Outstanding heat transfer efficiency with approach temperatures as low as 3°C (5.4°F) and crossing temperatures

- Excellent long-term operational reliability in cyclic, high-temperature duties

- High thermal capacity in a compact unit

- Fully welded, leakage-free design

- Perfect for duties with high loads, temperatures, and pressures, e.g. in molten salt applications

Unique features

FlexCoil

Serpentine coil design ensures maximum reliability and compact performance

The FlexCoil design uses serpentine tubes to effectively absorb thermal expansion under cyclic operating conditions and maximize operational reliability. The unique tube arrangement also increases the heat transfer surface area dramatically, enabling high thermal capacity within a compact shell.

HeaderTube

Tubular header for unparalleled reliability in cyclic duties

The circular header design increases the flexibility in the tube/header connections, ensuring thermal expansions and contractions are absorbed. In combination with fully checkable, high-strength welds, this robust design delivers outstanding operational reliability under cyclic operating conditions.

SecureFlow

Optimized flow distribution and mechanical stability

The SecureFlow guides eliminate bypass on the sides of the tube bundle, ensuring the hot medium only flows through the active coil area. They also secure the position of the tube bundle and reduce vibrations, enhancing mechanical reliability.

Ideal for large-scale steam generation systems

The transient nature of renewable energy sources such as wind and solar power requires heat exchangers in energy storage systems to handle intermittent operation and fluctuating conditions without compromising reliability.

They must also withstand high temperatures and pressures while delivering excellent thermal efficiency to maximize roundtrip performance.

Alfa Laval Aalborg header-and-coil heat exchangers are specifically designed to meet these demands, providing a robust and efficient solution for applications such as small modular nuclear reactors, large-scale energy storage systems – both power-to-power and power-to-heat – as well as concentrated solar power plants.

Header-and-coil heat exchangers are equally well suited for use as economizers, evaporators, superheaters, and reheaters. They can be delivered either as individual components or as complete, fully customized steam generation systems, including all heat exchangers, a steam drum, and necessary piping. Based on natural circulation, these systems offer stable operation with low OPEX and CAPEX.

Key applications

Power-to-heat energy storage

Header-and-coil heat exchangers are perfect for large-scale power-to-heat energy storage systems using molten salt, offering robust performance and excellent heat transfer efficiency.

Power-to-power energy storage

The high thermal efficiency of header-and-coil heat exchangers enables maximum energy recovery and electricity generation in power-to-power energy storage applications.

Concentrated solar power

The unique header-and-coil design ensures long-term reliability in cyclic operations, making header-and-coil heat exchangers a perfect fit for concentrated solar power plants

How it works

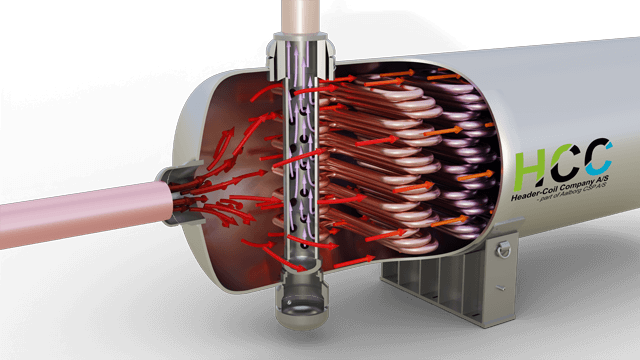

A header-and-coil heat exchanger consists of a pressure shell through which the heating medium – typically molten salt or thermal oil – flows from one end to the other. Inside the shell, a large number of tubes carry water and steam in the opposite direction.

The tubes have a serpentine shape, which increases their length and maximizes the heat transfer surface area. Combined with a counter-current flow, this design delivers outstanding thermal efficiency and enables approach temperatures as low as 3°C (5.4°F).

The serpentine coil arrangement also effectively absorbs thermal expansion, reducing mechanical stress and eliminating the risk of leaks.

The tubes are butt welded to a unique, cylindrical header. Thanks to the round header shape, thinner materials can be used without compromising pressure resistance, thereby increasing structural flexibility and ensuring long-term reliability under cyclic operating conditions. The design also allows for rapid temperature ramp-ups, supporting faster and more efficient plant operation.

Alfa Laval and Aalborg CSP launch header-and-coil heat exchanger for large-scale energy storage systems

Alfa Laval Aalborg Header-Coil A/S, a joint venture between heat exchanger manufacturers Alfa Laval and Aalborg CSP, has launched its first product in energy storage. The header-and-coil heat exchanger is specifically designed for use in large-scale thermal energy storage systems, offering high thermal efficiency, a compact footprint, and high reliability under cyclic operating conditions.