Aalborg OC

Aalborg OC is a high performance, combined oil and exhaust gas-fired boiler with a high capacity. The product is quick and easy install.

Aalborg OC is a high performance, combined oil and exhaust gas-fired boiler, with a 0.75-5 t/h capacity of the oil-fired section at 9 bar (g) design pressure.

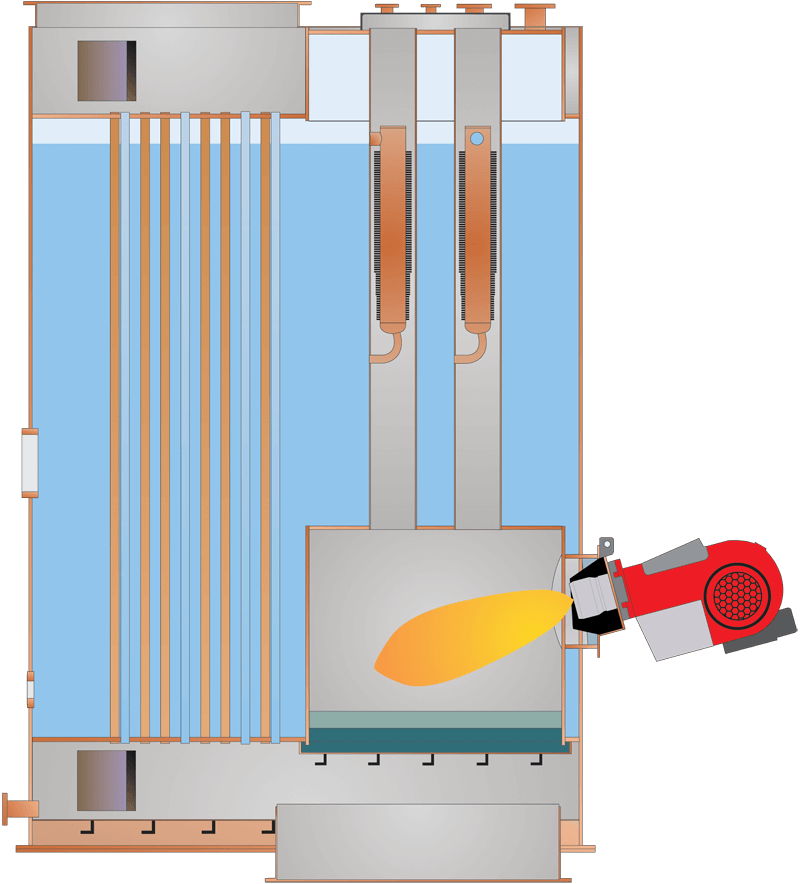

Aalborg OC is a vertical, cylindrical boiler with an exhaust gas section consisting of bare smoke tubes while the oil-fired section features pin tubes in the convection section

Features and benefits of the Aalborg OC product

- Vertical smoke/water tube type

- Standard preassembled boiler unit

- Integrated pin tube elements

- Integrated control panel

- Quick and easy installation

- Designed for operation with a monobloc-type pressure jet or rotary cup burner

How it works

Alfa Laval Aalborg rotary cup burner-

Aalborg KBE

The Aalborg KBE rotary cup burner is an optimized, standardized design of Alfa Laval's wellproven Aalborg KB burner. With the electronic air/fuel ratio control, an extremely precise combustion control is achieved. The Aalborg KBE burner is compact and low weight, and the control system user-friendly and safe.

- Capacity range: 0.3 – 0.97 MWe

150–1,300 kg/h

Alfa Laval Aalborg pressure atomizing burner-

Aalborg KBOG-E

Based on the proven Aalborg KBO-E modulating pressurejet burner, the Aalborg KBOG-E is a reliable dual-fuel burner that meets the growing demand for fuel flexibility onboard the world’s fleet. When used with small capacity Aalborg OS and OC boilers, it is suitable for firing liquefied natural gas (LNG) as an alternative to heavy fuel oil (HFO) and marine gas oil (MGO) onboard LNG carriers as well as other commercial vessels, such as tankers, bulk carriers and container ships carrying LNG bunker tanks.

Capacity

The Aalborg KBOG-E dual fuel burner is designed to fit small

Aalborg OS and Aalborg OC boilers ranging in steam capacity

from 1.6 - 6.5 t/h and 0.75 - 5.0 t/h, respectively.

Pin tube element

The boiler design has integrated pin tube elements. The pin tube elements support both the furnace and the boiler top plate. The design has been significantly optimized to achieve lower weight and improved strength. The result: longer lifetime of the pin tubeby a factor of 8.

Construction

Aalborg OC is a vertical boiler with an exhaust gas section consisting of bare smoke tubes. The cylindrical shell surrounds the smoke tubes, the furnace, the steam space and the convective section, which consists of pin tube elements. The boiler pressure part is manufactured from mild steel able to withstand high temperatures. Stress concentrations in corners are minimized by the simple design of cylindrical shells with flat plates of equal thickness.

Burner

Aalborg OC is equipped with a monobloc type pressure-jet burner. The burner is hinge-mounted and can be swung out for service and easy access to inspect the furnace. The burner housing is mounted on the boiler front, angled 15 degrees downwards against the furnace bottom. This allows for a long flame and offers better utilization of the furnace.

The flow of the combusting particles becomes optimal, and the result is a high performance combustion - even with the lowest grades of fuel. As an alternative, Aalborg OC can be equipped with a rotary cup burner.