Once through steam generator

Alfa Laval’s unique once through steam generators set a new standard for compact performance, combining the functionality of an economizer, evaporator, superheater and steam drum into a single, fully integrated unit. They can operate under a wide range of conditions, even at loads as low as 5%. This, in addition to the compact size and excellent reliability under highly cyclic operating conditions, makes once through steam generators the ideal choice for small to mid-scale energy storage systems

Benefits

- Compact design and minimum footprint

- A unique water separation and recirculation system enables stable operation at very low loads (5%) and ensures highly responsive operation

- Proven coil design ensures operational reliability in heavy-cycling, high-temperature operations

- Designed for easy access and maintenance

- Zero water discharge due to once through operation

Unique features

4-in-1

Complete steam generation system in one compact unit

The unique 4-in-1 design integrates the four functions of a complete steam generation system – including an economizer, evaporator, steam drum, and superheater – into a single shell. This ultra-compact, all-in-one design minimizes installation footprint and CAPEX while simplifying system integration.

HeliCoil

Coil-wound geometry for thermal flexibility and operational reliability

The HeliCoil spiral-wound tubes absorb thermal expansion during cyclic operation. This geometry reduces mechanical stress and ensures long-term reliability in demanding steam generation processes with frequent start–stop cycles. The spiral-wound tubes also maximize the heat transfer area, enabling high capacity within a compact shell.

FlexOp

Stable low-load performance and high responsiveness

The unique FlexOp water separation and recirculation system enables stable operation at loads as low as 5%. Combined with the HeliCoil and 4-in-1 features, it minimizes the hold-up volume, resulting in short response times and enhanced operational flexibility.

ElectroStart

Electric preheating for fast start-ups

ElectroStart is an integrated, electric preheating system that enables rapid warm-up and pressurization, increasing system availability by minimizing start-up delays.

The first-hand choice for small to mid-scale molten salt energy storage systems

Alfa Laval once through steam generators are tailored for use in compact, modular power-to-heat energy storage systems using e.g. molten salt as storage medium.

By integrating four key functions—economizer, evaporator, steam drum, and superheater—into a single, compact shell, Alfa Laval once through steam generators enable system builders to reduce installation footprint and optimize CAPEX.

The helical coil design ensures reliable performance under cyclic operation with significant temperature variations.

A unique water separation and recirculation system enables fast start-ups and stable operation at loads as low as 5%. Combined with the helical coils and 4-in-1 design, it helps minimize the hold-up volume, which in turn reduces response times and enhances system flexibility.

How it works

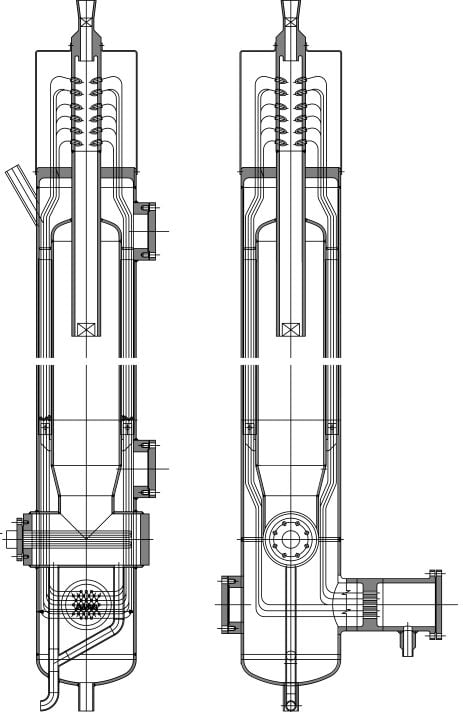

An Alfa Laval once through steam generator offers a complete steam generation solution in one compact, fully welded unit.

It consists of a pressure shell containing a helical coil bundle. Feedwater enters at the bottom and flows upward through the coil, where it is sequentially preheated, evaporated and superheated, resulting in saturated or superheated steam at the outlet. The heating medium, typically molten salt or thermal oil, flows in the shell side in the opposite direction, ensuring efficient counter-current heat transfer.

The helical coil design provides an extended surface area within a compact footprint. It also enables the unit to absorb thermal expansion, thereby reducing mechanical stress and enhancing fatigue resistance.

There are three modes of operation:

- Once through operation – The water flow is automatically controlled according to the load demand.

- Warm-up mode – The integrated electric heater enables controlled warm-up and pressurization of the unit, which is critical for molten-salt-based steam generators.

- Start-ups and low-load operation – To overcome the intrinsic limits of once through steam generators at very low loads, the system operates in circulation mode, generating wet steam. The steam is separated using an integrated separator, while the water is recirculated to ensure optimal tube cooling. Steam production is regulated via level control within the accumulation volume inside the exchanger.