Aalborg EH-S

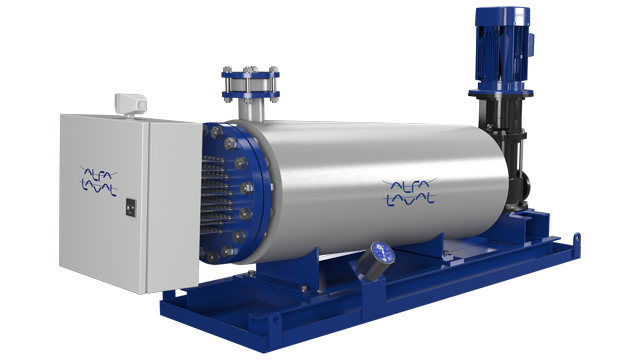

Aalborg EH-S (formerly VESTA™ EH-S) is a flow through electrical heat exchanger, ideal for steam production.

The Aalborg EH-S is installed horizontally and comes as a complete unit with control cabinet and pre-mounted pump, safety valve and non-return valve, ready for installation.

Connected to the auxiliary steam boiler, the Aalborg EH-S heater is for certain ship types replacing or acting as a Donkey boiler and an alternative to conversion of boilers for MGO operation. The Aalborg EH-S heater complies with European standards and is designed for easy approval by the classification socities.

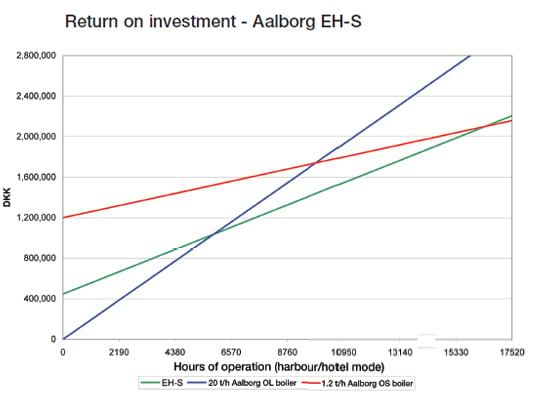

For certain ship types, the installation of the Aalborg EH-S electric flow through heater may be the ideal option for the socalled harbour / hotel mode. The return on investment is shown below based on the actual specifications and conditions of operation. The curves of the

diagram represent the typical investments and running costs for a 47,000 DWT Product Carrier with a 20 t/h boiler plant and an economizer.

The “EH-S” line indicates the gen-set operated electrical heater type Aalborg EH-S with a steam production of approx 300 kg/h usually considered sufficient for harbour / hotel mode. The “Aalborg OS” line indicates the investment and running costs for a 1.2 t/h boiler with a fuel oil consumption of 30 kg/h. The “Aalborg-OL” line indicates the running costs for an existing 20 t/h boiler with a fuel oil consumption of approx 80 kg/h. As this is an existing installation, the costs of investment are not considered.

For all curves, the fuel oil costs are based on a market price of USD 350 per metric ton (October 2009). Operational costs such as maintenance and the like are not considered in the curves. In addition to the direct investment and operational costs, a number of indirect costs and savings should also be considered. Amongst these are the extended lifetime and reduced maintenance of components, etc. of the oil-fired boiler plant if operation with a

turndown ration of approx 1:10 is avoided. Additionally, investment in the Aalborg EH-S heater or the

Aalborg OS boiler adds a 100% redundant steam system to the

existing boiler plant.

Design data

- Design pressure: 16 bar(G)

- Design temperature: 204°C

- Flanges: DIN86030, EN1092-1, JIS, PN16

- Mounting style: Horisontally

- Surface loads: 10.5 W/cm²

Suitable ship types

The typical type of vessels for the use of electric operated steam are:

- Product carrier

- Container vessels

Common for these type ofvessels are that they often only have a large oilfired boiler and an exhaust gas boiler installed and have frequent and short harbour visits

How it works

The heat load capacity range is up to 270 kW, with design conditions up to 16 bar(g) and 204ºC. The Aalborg EH-S is installed horizontally and comes as a complete unit with control cabinet and pre-mounted pump, safety valve and non-return valve, ready for installation.

Connected to the auxiliary steam boiler, the Aalborg EH-S can replace or act as a donkey boiler for certain ship types. Moreover, it is an alternative to conversion of boilers for MGO operation. The Aalborg EH-S complies with European standards and is designed for easy approval by the classification societies.

All dimensions are a guideline only. Dimension drawing will be produced upon request.